PowerForce

EUR 207,10

VAT not included

PowerForce

High cut and wear resistance for extreme durability, they handle sharp edges (≥2mm) without extra protection, ensuring safety and longevity

EUR 207,10

VAT not included

Available within 10-15 Days

- Extremely cut resistant

- Low weight

- Tear-resistant label covered with a protective sleeve

- Edge reinforcement with interwoven high-tech yarns to protect from wear

- Custom lengths on request

Select Model

EUR 207,10

VAT not included

Available within 10-15 Days

RFID transponder

Elect. test documentation and management system

The SpanSet premium heavy-duty round slings are fitted with an RFID transponder that is firmly integrated into the label, which – together with IDXpert – makes it easy for you to plan, carry out and document the regular inspections of work equipment.

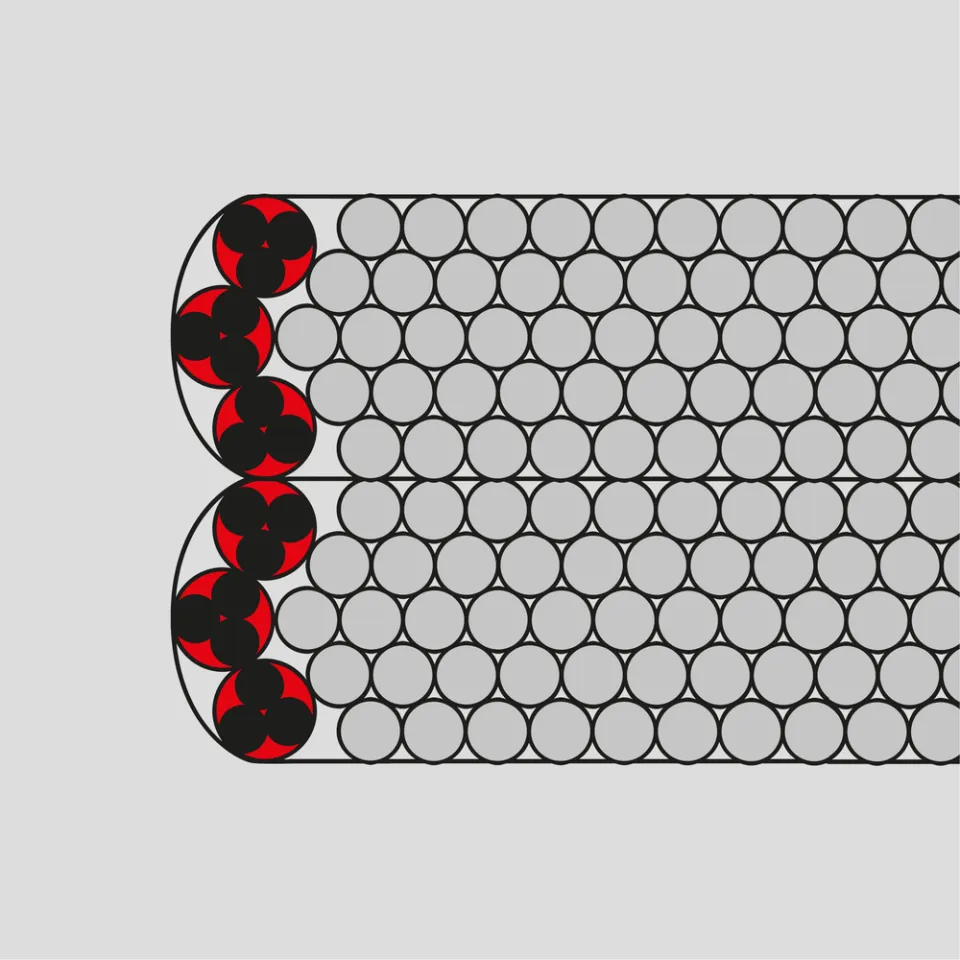

Reinforced edges

Resistant to wear and abrasion

Extremely hard-wearing high-tech black spun yarn is woven into the edges of the slings. They provide an easily recognisable protection against chafing on the edge of the strap. Your benefit: longer service life and lower costs!

High cut and wear resistance set PowerForce lifting straps

apart from polyester lifting straps with the same load capacity.

With its ever-expanding range of applications, the new PowerForce lifting strap is the ideal sling for the construction industry and mechanical engineering. Sometimes, you need to lift a precast concrete part with a rough surface, directly followed by a roof component or steel beam with extremely small edge radii. The PowerForce lifting strap is capable of withstanding any edge radius of more than 2 mm, even when dealing with the widest variety of mechanical components.

Increased safety, longer service life

The thing that makes PowerForce lifting straps special is the fact that the cloth is made out of extremely cut and tear-resistant high-performance fabric (high-modulus polyethylene). They require no additional protection when fastened around sharp edges with a radius of more than 2 mm. For conventional two-layer lifting straps, a radius that small is sharp enough to be strictly prohibited – for polyester lifting straps, an edge is considered sharp if the thickness of the sling material is greater than the edge radius.A protective sleeve is therefore required for the commonly used two-layer lifting straps when the edge radius is still as big as 6 mm. The low elasticity of the fabric is also a plus point – it ensures lifting force is quickly generated and allows for good control of the lifting manoeuvre.

Well thought-out seam construction

State-of-the-art, computer-controlled sewing machines ensure a consistently high seam quality – proudly Made in Germany. The main seam (box seam) in PowerForce lifting straps, sewn in black thread, is very small and therefore space-saving, which leaves a larger contact area for the load than with conventional lifting straps of similar length. What‘s more, the black thread on a white fabric makes visual inspections easier.

Robust, tear-resistant label with RFID tag

Each PowerForce lifting strap is equipped with a tear-resistant SpanSet quality label with an RFID transponder. PowerForce was designed based on the EN 1492-1 standard, which applies to polyester lifting straps, amongst other things. We say “based on” because the standard does not take HMPE into account, since the fabric and the label are in white.

You can rely on it!

SpanSet has examined and thoroughly tested the cut resistance of PowerForce lifting straps in both laboratory tests and fi eld trials. Amongst other things, the lifting straps have been subjected to alternating stress testing in which they were loaded up to capacity on a 2 mm edge radius 20,000 times – convincingly demonstrating the enormous cut resistance. And in the subsequent residual strength testing, the safety factor of 7 prescribed in the standard for production controls on new lifting straps (without shackles) was reached, surprising even the developer

Extra convenience

A combination of D1 and D2 shackles (pass-through shackles) is available especially for use when hitching up a load.

Product Technical Information

-

Safety Factor

7:1 -

Norms

EN 1492-1 -

Temperature Range

-40°C bis +60°C -

Webbing Thickness

3 mm -

Label Protection

Yes -

Belt Layers

1 -

Main Material

High molecular weight polyethylene (HMPE) -

Packaging Unit (PU)

pcs -

Packaging Unit (PU) Content

1

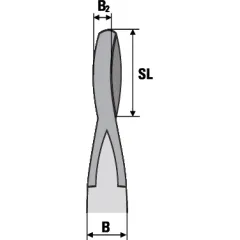

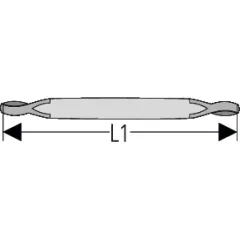

Technical Drawings

Variants information

| Item Number | Item Name | WLL kg | Weight per Meter | Weight Net | WLL t | Dimension L1 min | Dimension L1 | Loop Length | Loop Width | Webbing Width B | Colour | Weight for 1m |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2002972 | PowerForce 1ply 1000 2m | 1000 kg | 0.08 kg/m | 0.36 kg | 1 t | 1 m | 2 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2002973 | PowerForce 1ply 2000 2m | 2000 kg | 0.16 kg/m | 0.72 kg | 2 t | 1.2 m | 2 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2002974 | PowerForce 1ply 3000 2m | 3000 kg | 0.24 kg/m | 1.18 kg | 3 t | 1.5 m | 2 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |

| 2003442 | PowerForce 1ply 1000 3m | 1000 kg | 0.08 kg/m | 0.44 kg | 1 t | 1 m | 3 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2003443 | PowerForce 1ply 1000 4m | 1000 kg | 0.08 kg/m | 0.52 kg | 1 t | 1 m | 4 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2003444 | PowerForce 1ply 2000 3m | 2000 kg | 0.16 kg/m | 0.88 kg | 2 t | 1.2 m | 3 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2003445 | PowerForce 1ply 2000 4m | 2000 kg | 0.16 kg/m | 1.04 kg | 2 t | 1.2 m | 4 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2003446 | PowerForce 1ply 3000 3m | 3000 kg | 0.24 kg/m | 1.42 kg | 3 t | 1.5 m | 3 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |

| 2003447 | PowerForce 1ply 3000 4m | 3000 kg | 0.24 kg/m | 1.66 kg | 3 t | 1.5 m | 4 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |

| 2003937 | PowerForce 1ply 1000 5m | 1000 kg | 0.08 kg/m | 0.6 kg | 1 t | 1 m | 5 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2003938 | PowerForce 1ply 1000 6m | 1000 kg | 0.08 kg/m | 0.68 kg | 1 t | 1 m | 6 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2003939 | PowerForce 1ply 1000 8m | 1000 kg | 0.08 kg/m | 0.84 kg | 1 t | 1 m | 8 m | 300 mm | 30 mm | 40 mm | Purple | 0.18 kg |

| 2003940 | PowerForce 1ply 2000 5m | 2000 kg | 0.16 kg/m | 1.2 kg | 2 t | 1.2 m | 5 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2003941 | PowerForce 1ply 2000 6m | 2000 kg | 0.16 kg/m | 1.36 kg | 2 t | 1.2 m | 6 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2003942 | PowerForce 1ply 2000 8m | 2000 kg | 0.16 kg/m | 1.68 kg | 2 t | 1.2 m | 8 m | 300 mm | 40 mm | 80 mm | Green | 0.36 kg |

| 2003943 | PowerForce 1ply 3000 5m | 3000 kg | 0.24 kg/m | 1.9 kg | 3 t | 1.5 m | 5 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |

| 2003944 | PowerForce 1ply 3000 6m | 3000 kg | 0.24 kg/m | 2.14 kg | 3 t | 1.5 m | 6 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |

| 2003945 | PowerForce 1ply 3000 8m | 3000 kg | 0.24 kg/m | 2.62 kg | 3 t | 1.5 m | 8 m | 400 mm | 50 mm | 120 mm | Yellow | 0.59 kg |