Vertical transport of plates - universal

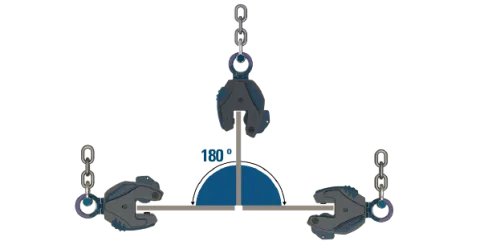

Exoset universal vertical safety lifting clamps are suitable for the lifting, turning (180°), moving and vertical transfer of sheet materials, plates and fabrications. Plates can also be turned from horizontal to vertical and back down to horizontal (180°).

All Exoset universal vertical safety lifting clamps are fitted with a locking device for both open- and closed positions, which ensures complete safety. The universal hoisting eye allows the clamp to place and lift the load from any direction, or with a multiple leg sling without side-loading the clamp.

Improved safety

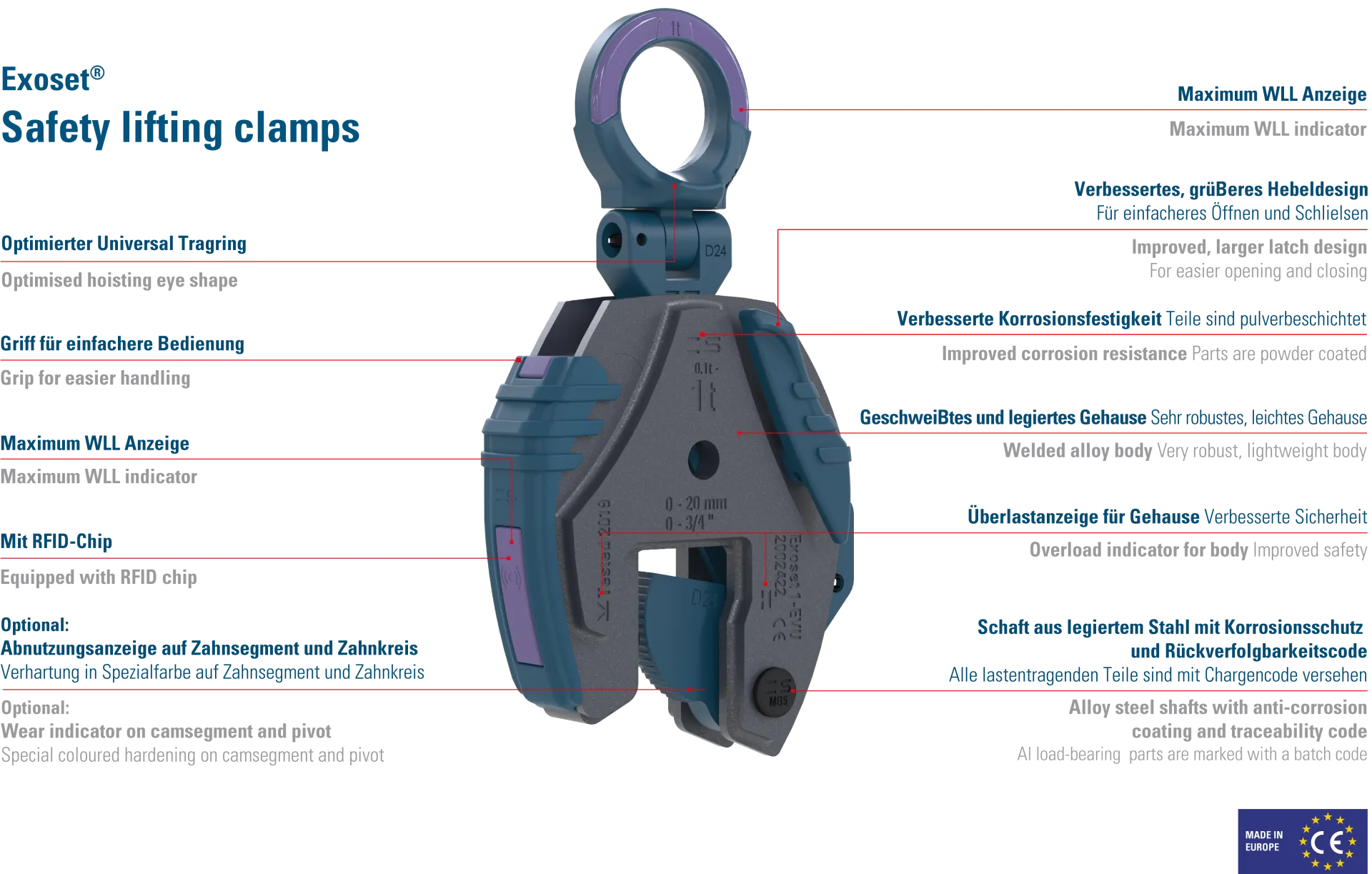

We added a maximum WLL indicator, located where it is clearly visible on the hoisting eye and the grip. This Indicator makes it easy for the user to recognize the maximum load for which the lifting clamp can be used. Additionally we improved safety by adding an overload indicator as well as a corrosion resistant layer. There is also an option for a wear indicator. These innovations improve safety on the shop floor!

UNIVERSAL VERTICAL LIFTING CLAMPS

- Available in capacities 0.5t-6t. Higher WLL and different jaw apertures are available upon request.

- Lock open, lock closed ability with latch for pre-tension on load and then release of load

- Breaking Load Limit of 5x WLL

- Load cycles until Exoset universal vertical safety lifting clamps are unusable (tested in vertical position); 500.000 load cycles

- For use with materials with a surface hardness up to 364 HV, tensile strength 1200 N/mm2

- Minimum WLL needed is 10% of maximum WLL

- Temperature range -40°C/104°F - +100°C/212°F

- Each clamp is individually serialized. Serial number and date of Proof Load test are permanently marked on the body

- All load-bearing parts are marked with a traceability code and the SpanSet logo to guarantee the original, highest-quality SpanSet parts.

- Individually Proof Tested to 2x the Working Load Limit with certification

- Instruction manual and test certificate included with each clamp

- Service and repair manual available through SpanSet website

- Maintenance and overhaul kits for all clamps are available. All Exoset safety lifting clamps are RFID equipped.

- Exoset safety lifting clamps are the only safety lifting clamps in the world certified by DNV

- EVU H for vertical lifting, transporting and turning of all steel plates with a maximum hardness of 473 HV, tensile strength 1550 N/mm2. (for example Hardox 400 and 500)

- EVU S for vertical lifting, transporting and turning for stainless steel plates. With a maximum hardness of 364 HV, tensile strength 1200 N/mm2.

- 5 Year Warranty

The only lifting clamps in the world certified by DNV

- DNV Type Approval – ST – 0378

- European Norm EN 13155

- USA Norm ASME B30.20, Design category C, Service class 4

- USA Norm ASME BTH – 1

- Australian Norm 4991

- CE - European Machine Directive 2006/42/EC

55 years of SpanSet

Experience pays off

Powder coated and corrosion resistant.

With indicator for overload and load capacity.

✓ Repair service

✓ Specialist consultation.