There is no expiration date for lashing straps, but…

Question: How many years is a lashing strap for load securing (see illustration 7) allowed to be used on motor vehicles, vehicle combinations, and trailers? Counter question: How long is a car allowed to participate in road traffic?

Answer to both questions: As long as the technical and safety-related requirements are demonstrably met. – There is a lot to consider on this topic. What you should know is explained in this guest article.

by Werner Glasen (SpanSet Deutschland GmbH)

1 Basics

Manufacturers are often asked whether tie-down straps for load securing have a minimum shelf life (MHD) or, like medications, even an expiration date. The answer is: No, there is none. Based on our experience, tie-down straps can be used for many years and sometimes even decades when used properly, stored correctly, and maintained well.

This is good news in itself, as there is fundamentally nothing to prevent a long and thus sustainable use of tie-down straps. But caution! No one certifies a tie-down system with an unlimited lifespan.

Instead, the service life depends on the technical condition of the tie-down straps. In this regard, the relevant guidelines and standards, such as VDI 2700 and EN-12195, primarily place the responsibility on drivers, loaders, and entrepreneurs. Each of them is jointly responsible for answering the question of whether a tie-down strap can be used in a specific case or if it should be discarded.

2 Operating instructions

The manufacturer should provide practical instructions for the use and maintenance of every tie-down strap and tie-down system. Adhering to the operating manual should be a matter of course for every driver, loader, and entrepreneur.

3 Check before each use

before the first use of a lashing system, it must be ensured that it complies with the applicable standards and has a permanently attached, legible label. The required information includes, among other things: Lashing Capacity (LC), Standard Hand Force (SHF), and – for systems used for downward lashing – the Standard Tension Force (STF)

Furthermore, most operating instructions (including those from SpanSet Germany) stipulate that the lashing strap must be checked for obvious defects before each use."

Signs of damage include:

· Incomplete, missing, or illegible information on the label. The required information includes, among others: Lashing Capacity (LC), Standard Hand Force (SHF), and – for tie-down lashing systems – Standard Tension Force (STF).[1]

· Deformations, cracks, severe signs of wear and corrosion on end fittings and clamping elements.[2]

· Cracks, cuts, notches and breaks in load-bearing fibers and seams, deformations due to heat in webbing.[3]

4 Regular inspection by a “competent person”

At least once a year, the securing devices must be inspected by a "qualified person" (formerly known as "competent person"). The operating manuals provide guidance for the inspection. The results must be documented in accordance with the BetrSichV (German Ordinance on Industrial Safety and Health). It is recommended to use a digital system, a test log, or a test book for this purpose. The following should be recorded: date and type of inspection, results, identified deficiencies, and the inspection verdict.

The EN 12195 describes the qualification evidence required for a "competent person." This includes, among other things, appropriate training, expertise, and practical experience. Guidelines for training are provided in EN ISO 9002:1994, Section 4. [4]

Depending on the operational circumstances, shorter inspection intervals may be required. Please note: Lashing systems are work equipment for which the employer must determine and establish the type, scope, and deadlines for inspections as part of the risk assessment.

5 Maintenance and repair

The VDI 2700 allows 'qualified persons' to perform maintenance and repair work. The 'qualified persons' are then responsible for restoring the original properties of the lashing device (see Figure 6). Manufacturers are more restrictive in this regard. In their operating instructions, it is usually stated (also by SpanSet Germany) that repairs and maintenance work on their products are reserved exclusively for themselves or for persons they have authorized.

6 Labeling

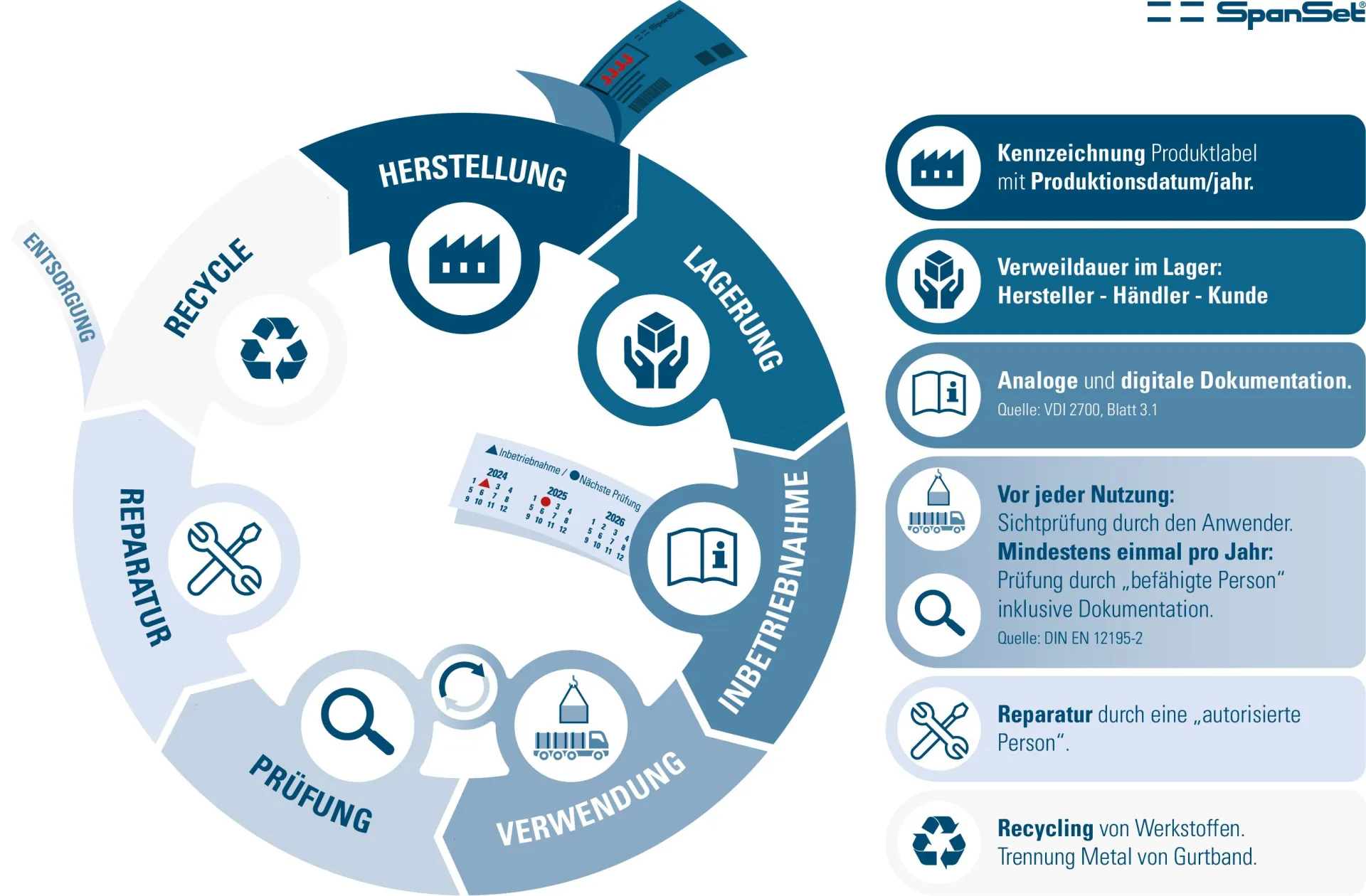

Each lashing strap requires a permanently attached product label. It must include, among other information, a traceability code (e.g., for recalls) and the date of manufacture (see Figure 1 and Figure 2).

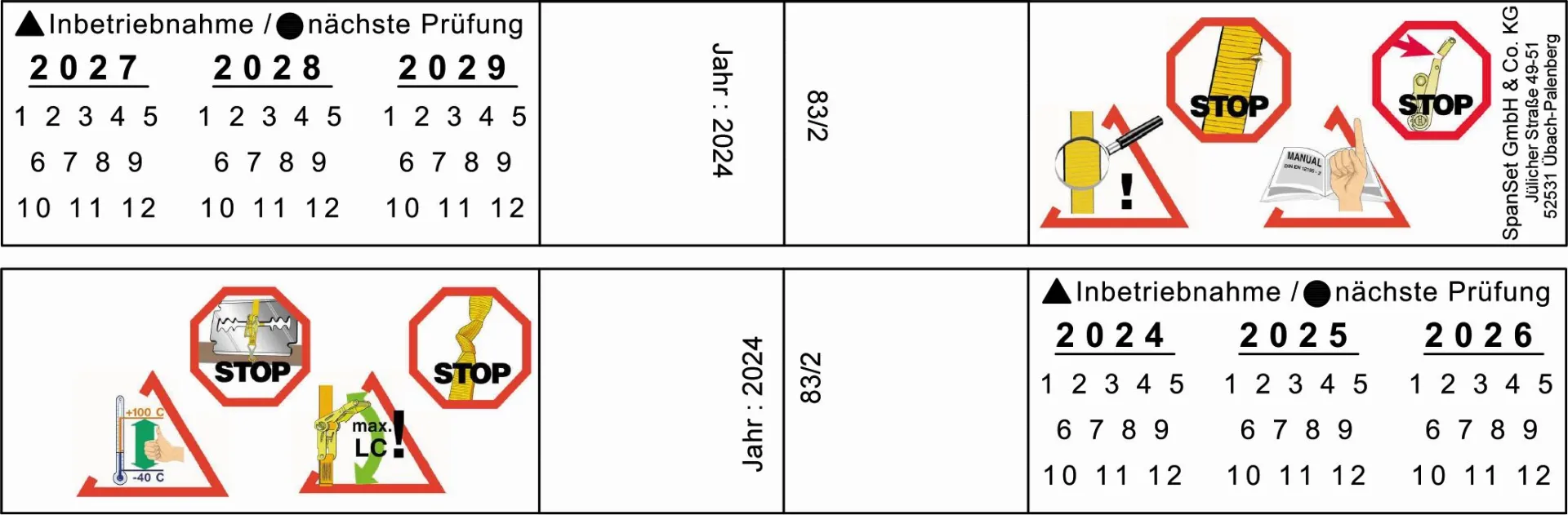

Straps from SpanSet Germany feature an additional label that simplifies the documentation of commissioning and annual inspections (see Figure 3 and Figure 5). The user can mark the commissioning and the first six annual inspections with a waterproof pen. Additionally, written or digital documentation of the defined inspection intervals is mandatory (cf. Paragraph 4: Regular inspection by a 'qualified person').

The indication of the manufacturing date on the label often leads to inquiries about the supposed 'minimum shelf life.' This is also because there can be a gap of twelve months or more between production and first use. In this case, it applies that as long as the lashing strap has been stored according to the manufacturer's specifications, the user has a new product at the time of commissioning—even a few years after production (see Figure 4: Lifecycle of lashing systems).

7 Concluding remarks

The bottom line remains: There is no expiration date for lashing straps. However, lashing straps may only be used under certain conditions. If in doubt, I recommend consulting the manufacturer or another qualified professional.

High-quality tie-down straps are robust tools for proper load securing in accordance with the Road Traffic Regulations. It states (§ 22 Load, para. 1): 'The load, including devices for load securing and loading equipment, must be stowed and secured in such a way that it does not shift, fall over, roll back and forth, fall down, or produce avoidable noise even in the event of a full brake or sudden evasive maneuver.' The paragraph ends with an important note for every user: 'The recognized rules of technology must be observed."

What does that mean?

The VDI 2700, which my statements primarily refer to, is neither a standard nor a law. However, it is considered an "accepted rule of technology" and is often referenced in legal disputes—such as when it needs to be clarified whether a load was properly secured, whether a specific lashing strap was allowed to be used, or how it should be used. Therefore, I would like to emphasize once again: the absence of a minimum shelf life does not mean that a strap can be used indefinitely without any restrictions.

Footnotes:

[1] Best before date

[2] EN 12195-2:2000; Annex B (normative) Practical instructions for the use and maintenance of lashing straps, which must be supplied by the manufacturer, page 22

[3] EN 12195-2:2000; Annex B (normative) Practical instructions for the use and maintenance of lashing straps, which must be supplied by the manufacturer, page 22

[4] Load securing devices on road vehicles Safety Part 2: Lashing straps made of synthetic fibers German version EN 12195-2:2000 EN 12195-2:2000. Page 8

Werner Glasen has been working in various positions for SpanSet Deutschland GmbH (Übach-Palenberg) since 1991. Over 20 years ago, he took on the leadership of product management, sales, and marketing.

Fig. 1: Product label with manufacturing year and traceability code as a barcode and numerical sequence (i) for (a) fixed and (b) loose. Lashing systems with STF indication are suitable for downward lashing

Fig. 2: Product label with manufacturing year and traceability code as barcode and numerical sequence (i). Lashing system suitable for direct and diagonal lashing without STF indication

Fig. 3: SpanSet additional label (front side), the month of commissioning is marked with a triangle. A dot indicates when the next inspection is due. Additionally, SpanSet additional label (back side).

Fig.4 : Life cycle of lashing systems (lashing straps)

Fig. 5: Sewing of the additional label (Fig. 3) together with the product label (Fig. 1 and Fig. 2) onto the lashing system. The additional label serves, among other things, for identification and documentation.

Figure 6: As described in the text (Section 6), the manufacturer SpanSet carries out repairs and maintenance on lashing systems.

Fig.7: Application example of an ErgoABS lashing system