ABS 2,500/50

ABS 2,500/50

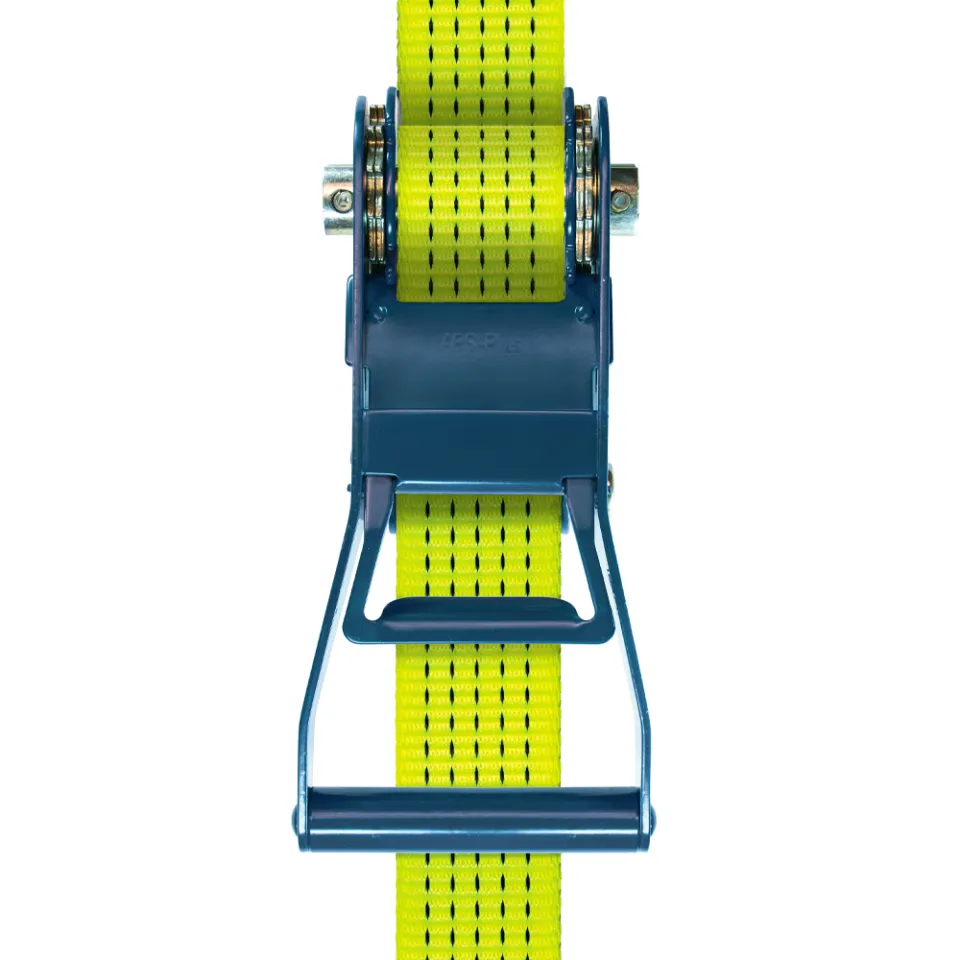

Robust and durable ratchet with progressive release, for safe release of tension and no load tipping

- Tensioning device with epoxy powder coating

- Robust rip-proof label, protected by plastic sleeve and webbing insert

- Ratchet tension can be released gradually, self-locking handle and equipped with double slider mechanism

- Low-stretch, wear-resistant webbing with cord edge protection and marking stripes

"Anti-Belt-Slip" procedure

Controlled tension liberation

The ABS system was developed for loads with a risk of tipping and allows the user to release the pretension in small steps. The lashing can also be opened completely.

Self-locking ratchet lever

Prevents unintetional opening

The ratchet opening during transportation is thus effectively ruled out - eben when the load is exposed to strong vibrations and shaking.

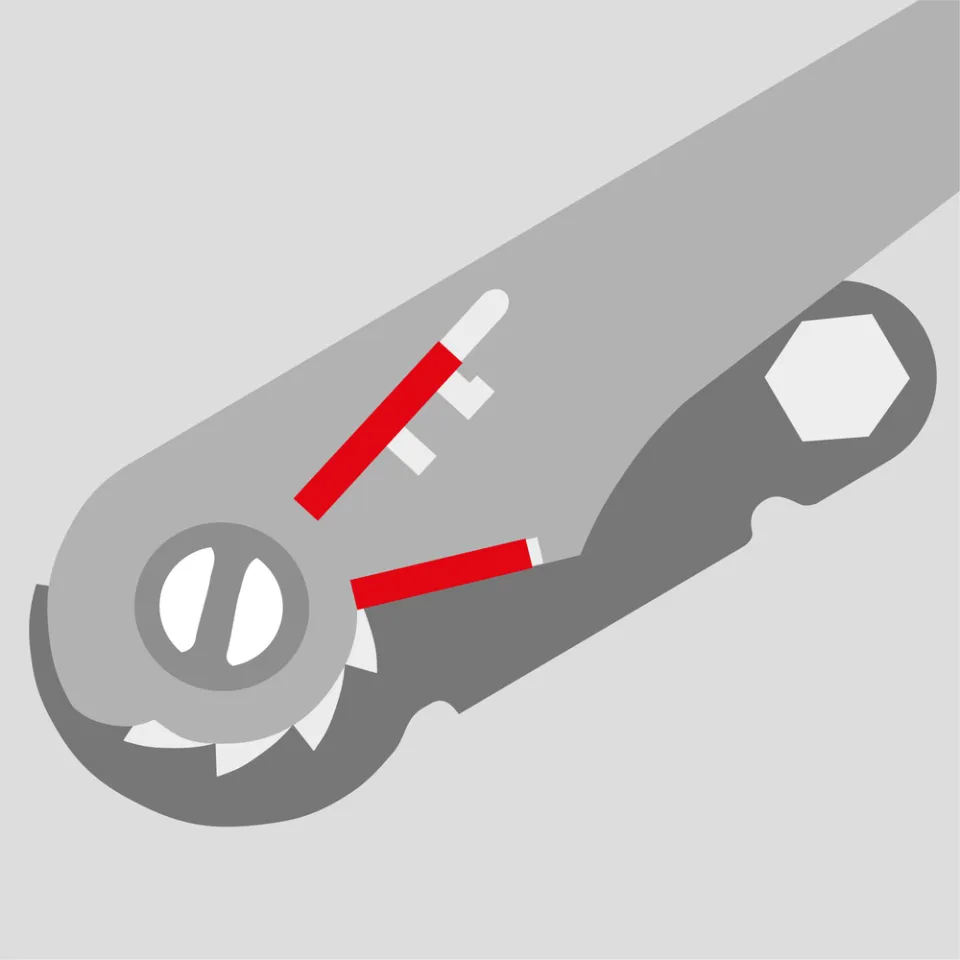

Double Slider

Safe in the intermediate phase when tensing

Secures in the intermediate stage when tensioning the webbing. Two sliders engage in an existing sprocket in "smaller steps".

Epoxy resin coating

Maximum ratchet protection

Ratchets are first zinc-plated, then chrome-plated and coated with a shock-resistant epoxy resin coat which additionally protects the ratchets from e.g. rust.

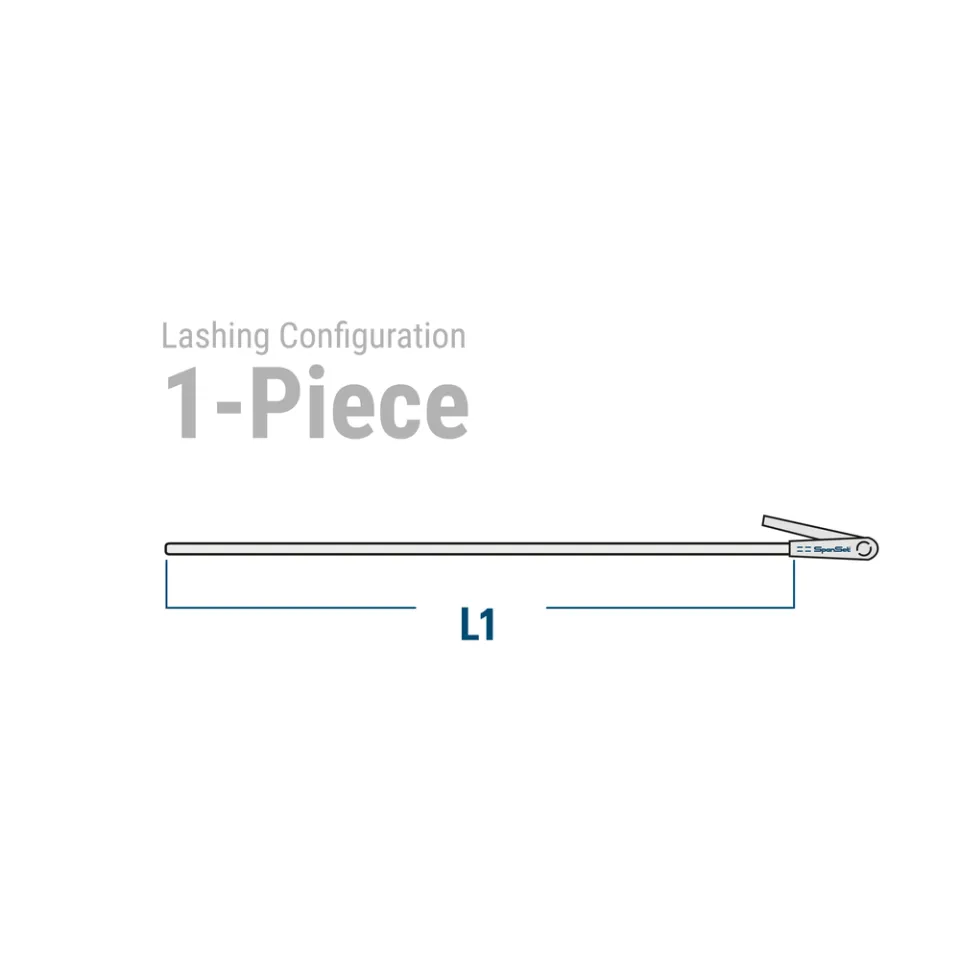

Precision strap

Low elasticity of the strap

Less stretch maintains more tension and reduces the need for tension readjustment.

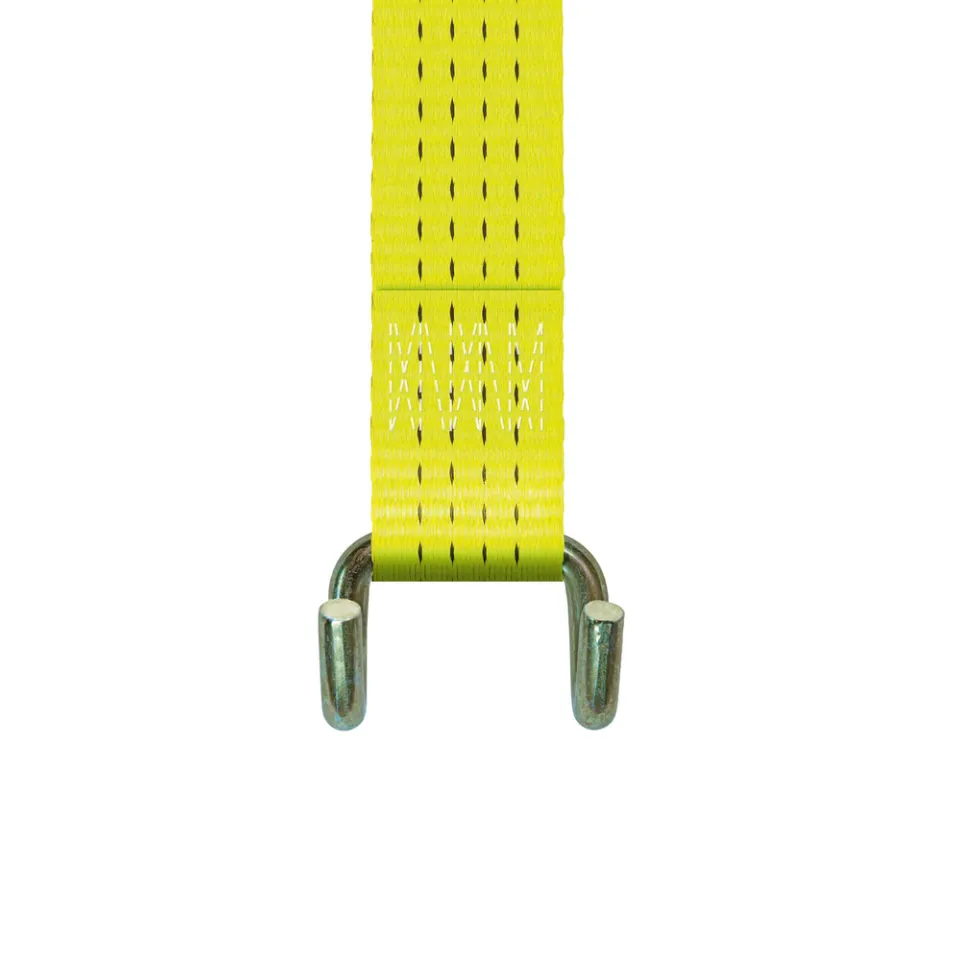

Reinforced edges

Longer service life and lower costs!

Webbing with the reinforced edge is more resistant to wear and abrasion.

Protective sleeve label

optimally protected, reinforced with selvedge

In addition to the tear-resistant design with a fabric lining, a robust plastic sleeve perfectly protects the writing from abrasion and dirt. The webbing insert, equipped as standard, also prolongs the service life.