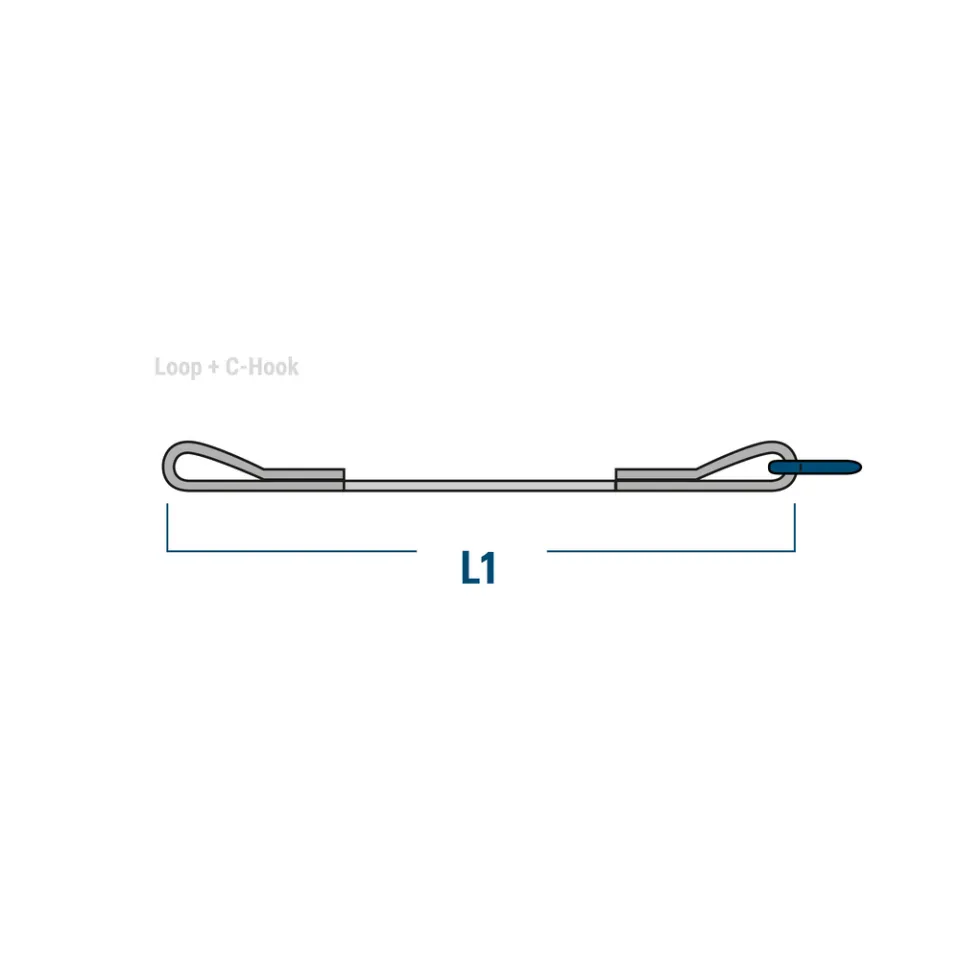

PowerFlex with Loop and C-Hook

PowerFlex with Loop and C-Hook

Abrasion resistance full coated lifting sling with loop and C-Hook

- High abrasion resistance.

- For raw surfaces.

- Colour-coded and with sewn-on load capacity indication.

- Full-surface loop reinforcement protects against chafing in the crane hook.

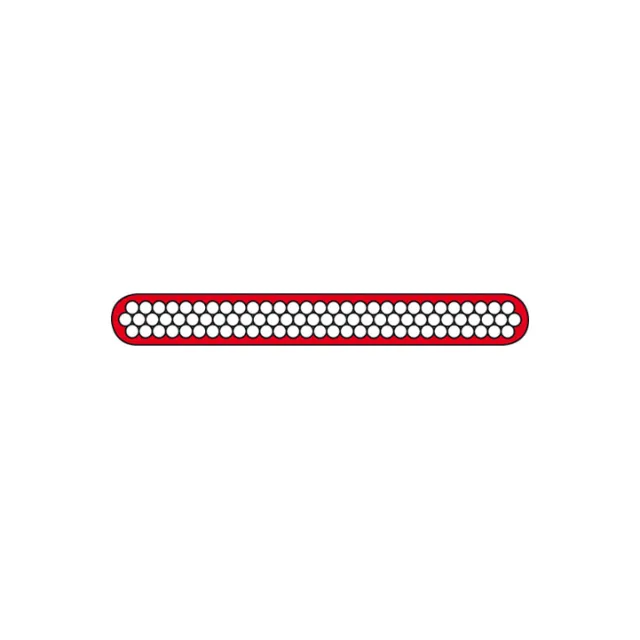

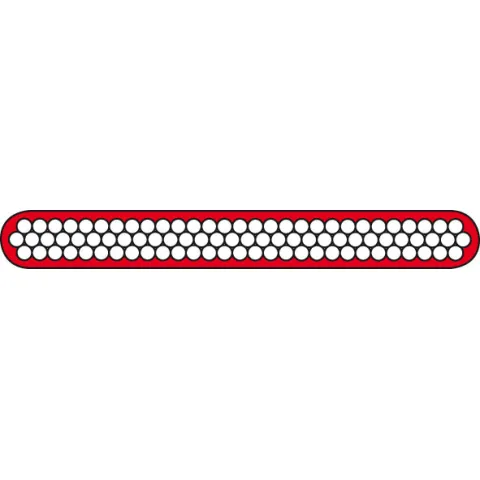

Flat sling coating

Protects against cutting of the lifting gear

Flat slings can be coated with secutex on one or on two sides, which provides for one-sided or all-around protection of the flat slings. This makes them more robust and protects against sharp-edged loads.

Woven load capacity indicator

Easy to read even when dirty

Speed is often of the essence in everyday work. To make sure you always use the right round sling, the load capacity indicator is firmly woven into the sleeve and can be read even when the sling is very dirty.

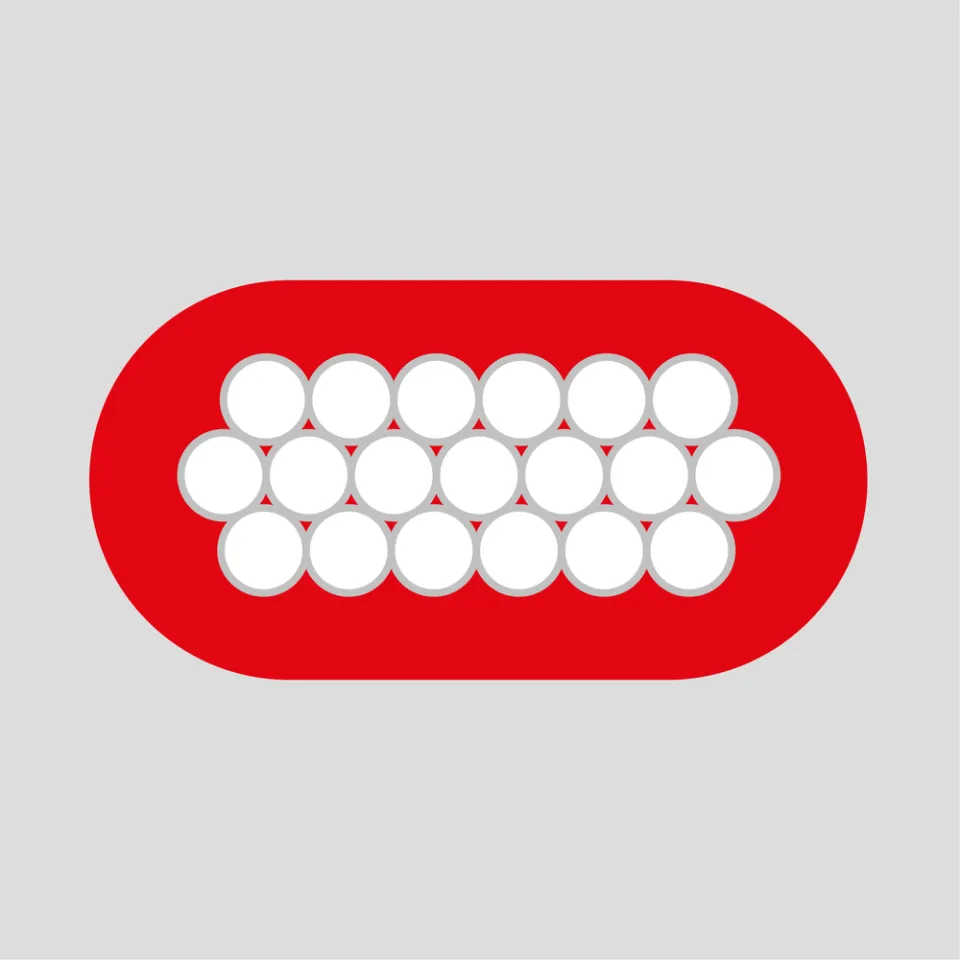

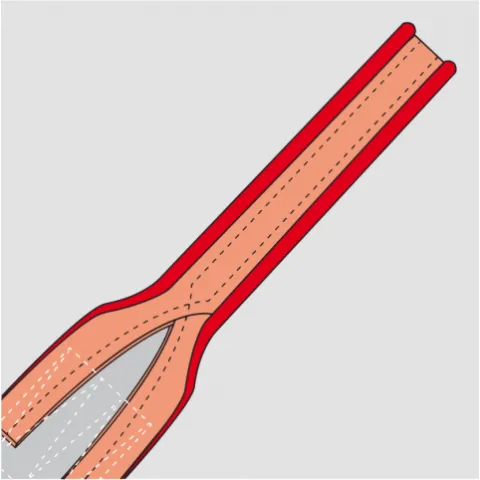

Flat sling loop reinforcement

Added protection against abrasion

Loops have to withstand a great deal of stress during lifting, hooking in and hook- ing out. The solution: loop reinforcement made of high-performance fibres. Thanks to the robust fibre layer, the load-carrying fabric is much more resistant to abrasion, thus prolonging its service life.

PowerFlex P2 - Fully coated

Coating on both sides

"Powerflex" is used wherever fabric protection and extreme abrasion resistance are paramount and the high flexibility of the lifting strap is to be maintained on the other hand. Since the lifting strap is completely coated, both sides can be used as a stop side. Dangerous mix-ups are thus a thing of the past.

Abrasion and fabric protection

Foreign particles and liquids usually easily penetrate the textile fabric of the lifting strap. If the soiled lifting strap is loaded, foreign particles can cut individual textile fibres and penetrating liquids can reduce or even eliminate the overall load-bearing capacity of a lifting strap. In view of the present operating conditions, protection of the fabric is therefore essential. "Powerflex" is a particularly thin spray coating. Due to the special manufacturing process, "Powerflex" can penetrate very deeply into the fabric, completely encasing the textile strands. Foreign particles and liquids can thus no longer penetrate and can be easily removed from the belt surface.