Different versions of a sharp edge

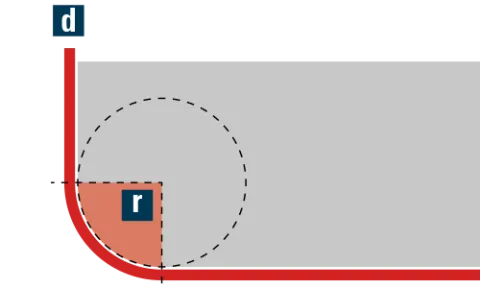

Edge radius

If the edge radius "r" is smaller than the thickness of the flat sling/round sling "d" , the edge is considered "sharp". Lateral movements or surface pressure can already be enough to sever the lifting gear.

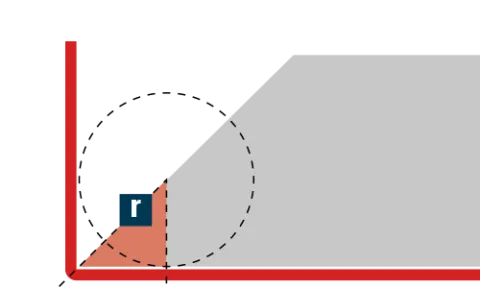

Edge angle

In addition to loads with rectangular edges, there are goods with deviating shapes. These include loads with protruding edges and with sharp or jagged outer contours, such as cogwheels, turbine blades etc. These edges cannot be determined by the general rule.

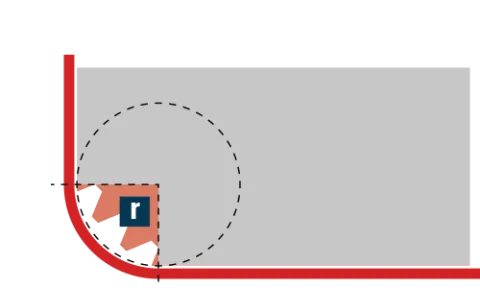

Edge shape

The shape and surface finish of the edges have a significant impact on the durability of the lifting gear. Very rough surfaces, such as those of a prefabricated concrete component, can very quickly damage textile lifting gear or a wire rope.

Tools for measuring radii

In order to assess the sharp edge, „tools“ are required.

The following tools can be used to determine radii:

- Radius gauge [a]

- Vernier caliper [b]

- Folding ruler

Shielding against Sharp edges

NoCut sleeve is a woven protective sleeve made from UHMPE [Ultra High Molecular Polyethylene] for lifting slings and roundslings, which is simply fitted into the lifting sling.

Other solutions for Sharp Edges

HMPE slings

HMPE [Heavy Duty High Capacity Performance] webbing is 50% thinner than conventional slings. This allows it to be used in tighter edge radii than conventional PES slings.

Slings with fused Secutex

Slings with Secutex have protection on one or both sides, along the entire length of the sling.

Protections

Using No-cut and anti-abrasion protections will extend the life of your equipment while improving safety for employees.

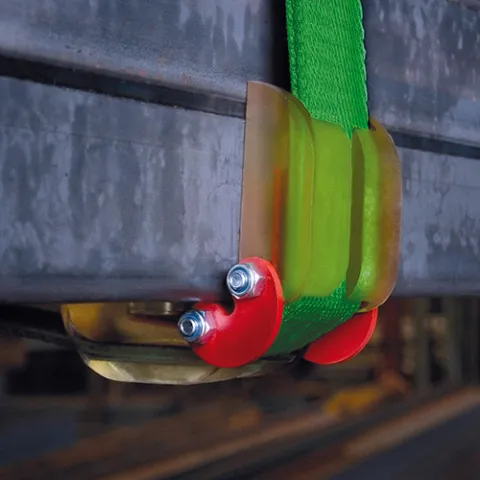

Corner protectors

The best defence is a good attack! By protecting the edges of the load, the radius of the load can be enlarged and its cancelled cutting capacity.

FREE POSTER

Create safe workspaces

Complete the contact form to receive our load poster.