Services

designed to best suit your requirements >

At SpanSet

Benefit from SpanSet's wide range of excellent facilities.

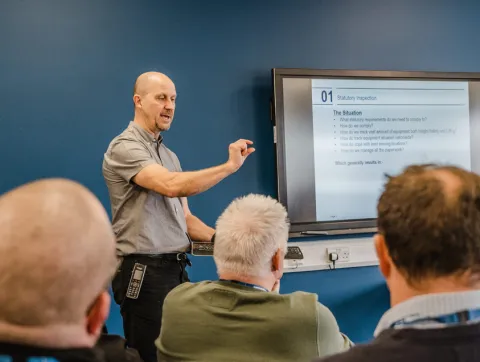

Use SpanSet as a 'Central Hub' - bring equipment from multiple work sites to us for inspection. Take advantage of our excellent facilities for workforce training, medicals, meetings etc.

- Ideal when no central hub is available within your premises.

- Maximises use of 'down time'.

Our Inspection Team comes to you

Mobile Team with National Coverage

Arrange for your workforce and/or their equipment to be gathered at a suitable location/s. Our experienced Inspection Team travels nationwide and will inspect equipment at a time and place convenient to your business. Also, an ideal solution for inspecting permanently installed systems.

- Convenient – a quick and efficient inspection service with equipment staying on site.

- Ideal for equipment that is on a restricted site, too large/uneconomical to move, in constant use or permanently installed.

Services

designed to best suit your requirements >

At SpanSet

Benefit from SpanSet's wide range of excellent facilities.

Use SpanSet as a 'Central Hub' - bring equipment from multiple work sites to us for inspection. Take advantage of our excellent facilities for workforce training, medicals, meetings etc.

- Ideal when no central hub is available within your premises.

- Maximises use of 'down time'.

Our Inspection Team comes to you

Mobile Team with National Coverage

Arrange for your workforce and/or their equipment to be gathered at a suitable location/s. Our experienced Inspection Team travels nationwide and will inspect equipment at a time and place convenient to your business. Also, an ideal solution for inspecting permanently installed systems.

- Convenient – a quick and efficient inspection service with equipment staying on site.

- Ideal for equipment that is on a restricted site, too large/uneconomical to move, in constant use or permanently installed.

Example inspection situations SpanSet can help with:

Contracts Manager -

Responsible for training, arranging medicals etc. for field-based teams, and who has no access to a central hub.

At SpanSet’s excellent facilities we can coordinate inspections and as required, Training, team meetings, medicals and so on, making the best use of ‘downtime’ with equipment inspections.

SHEQ Advisor -

At times a ‘hybrid solution’ is the most efficient.

When workforce equipment inspection and worker training requirements coincide – visiting SpanSet is the answer.

For the remainder of the workforce, when anniversaries for inspection and training do not coincide, the SpanSet Inspection Team can visit customer sites to conduct the thorough examinations.

Stores Manager -

Needing large volumes of key items of equipment independently inspected, tested, compliant and back available to use on site as quickly as possible.

Our Inspection team visit the customer stores/site and fulfil all inspection and record keeping requirements, ensuring downtime, lack of access and transport of equipment is kept to a minimum.

Health & Safety Officer –

Responsible for multiple customer sites based at various geographical locations.

Not feasible/economical to gather equipment at one central hub for inspection. Our Inspection engineers travel nationwide and efficiently visit multiple sites to carry out inspections.

What we

inspect >

Personal Fall Protection Equipment

Harnesses, helmets, lanyards, fall arrest and recovery blocks, temporary safety lines, rescue equipment, connectors, anchor slings and devices.

Engineered Fall Protection Equipment

Tripods, davit systems, anchorages and winches.

Lifting Equipment

Accessories

Roundslings, webslings, shackles, chain slings and wire ropes.

Lifting Equipment Machines

Chain blocks, lever hoists and wire rope pullers.

Installed and Engineered Fall Protection Equipment

Permanently installed horizontal & vertical fall protection systems, anchorages and accessories.

What we inspect >

Personal Fall Protection Equipment

Harnesses, helmets, lanyards, fall arrest and recovery blocks, temporary safety lines, rescue equipment, connectors, anchor slings and devices.

Engineered Fall Protection Equipment

Tripods, davit systems, anchorages and winches.

Lifting Equipment Accessories

Roundslings, webslings, shackles, chain slings and wire ropes.

Lifting Equipment Machines

Chain blocks, lever hoists and wire rope pullers.

Installed and Engineered Fall Protection Equipment

Permanently installed horizontal & vertical fall protection systems, anchorages and accessories.

Advantages of SpanSet's Managed Contract Equipment Inspection & Testing Service

Proactive - never be at risk of equipment being out of inspection date.

We will keep you informed and schedule reinspection in good time. Instant online access available to IDXpert Asset Management System database.

Benefit from SpanSet's wide range of excellent facilities.

Whilst equipment is being inspected at our site, maximise the use of 'downtime' - hold meetings, receive training, attend medicals etc.

Convenience - a mobile team with national coverage

We can conduct inspections and servicing across the whole of the UK. Co-ordinate inspections with existing plans to bring together your workforce and/or equipment.

Peace of mind.

SpanSet Inspection Services leaves customers free to concentrate on other aspects of their business. Compliance with inspection regulations and legal obligations is assured and SpanSet will maintain customer records for future tracking and reference.

SpanSet are safety equipment specialists

We design, manufacture, supply and install a wide range of height safety and lifting products. We have a depth of knowledge in equipment and hold a wide range of spares for ease of replacement and repair.

SpanSet Team

Our highly trained inspectors have extensive industry experience offering a consistently high standard of inspection.

IDXpert Asset Management

SpanSet use IDXpert Management. All items we inspect are RFID tagged to digitally trace the exact time, inspector, location and duration of inspection for full accountability with records maintained for future reference.

Reporting

All inspected equipment is returned with a condition report and certificate for items that pass (digitally, with duplicates available).

Equipment Inspections and Record Keeping

Why? How Often? Who by?

Check out our 'no nonsense' guide to Equipment Inspections

Have a question? Need to book an Inspection?

Send your enquiry and a member of our Team will be back in touch or call now on 01606 734279.