Mengenali Tanda-Tanda Kerusakan pada Webbing Sling SpanSet

Webbing sling SpanSet adalah alat angkat yang penting di berbagai industri dan kegiatan. Alat ini dapat digunakan untuk mengangkat dan memindahkan beban berat dengan mudah dan efisien. Namun, seperti semua alat, webbing sling SpanSet rentan terhadap kerusakan. Oleh karena itu, sangat penting bagi pengguna SpanSet untuk memahami tanda-tanda kerusakan agar dapat mengambil tindakan yang tepat untuk memastikan keselamatan selama penggunaan.

Berikut adalah beberapa tanda kerusakan yang perlu diperhatikan pada webbing sling SpanSet:

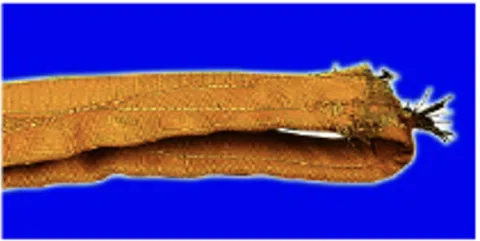

- Jahitan Longgar dan Banyak Goresan. Jahitan pada webbing sling SpanSet harus selalu diperiksa dengan cermat karena bertanggung jawab untuk menahan beban. Jahitan yang longgar atau banyak goresan menunjukkan kerusakan signifikan pada webbing sling. Jahitan yang longgar dan goresan dapat mengurangi kapasitas angkat webbing sling dan meningkatkan risiko kegagalan saat digunakan.

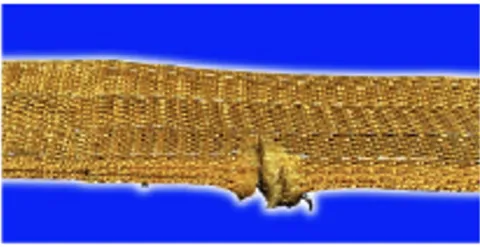

- Kusam dan Usang. Webbing sling SpanSet yang sudah kusam dan usang kehilangan kekuatan dan daya tahannya, sehingga mengurangi kemampuannya untuk menahan beban dengan aman. Bahan webbing yang sudah usang juga dapat retak dan pecah, memperburuk kondisi webbing sling dan membuatnya lebih rentan terhadap kerusakan.

- Perubahan Warna Akibat Paparan Panas. Jika webbing sling SpanSet terpapar panas, seperti ditinggalkan di bawah sinar matahari terlalu lama, warna webbing dapat berubah. Webbing yang memudar atau berubah warna menandakan bahwa telah terkena paparan panas dan mungkin rusak, terutama jika paparan panas terjadi dalam jangka waktu yang lama.

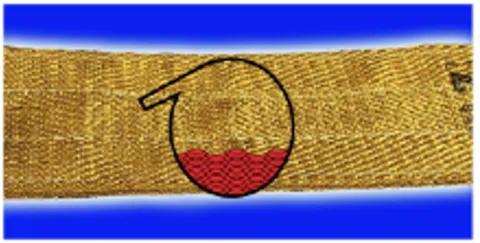

- Simpul di Area Belt. Simpul pada webbing sling SpanSet dapat mengurangi kekuatannya dan meningkatkan risiko kegagalan. Simpul dapat menekan webbing dan merusak serat-seratnya, sehingga webbing lebih rentan terhadap kerusakan. Selain itu, simpul yang terlalu kencang dapat menipiskan webbing, membuatnya lebih mudah putus saat digunakan.

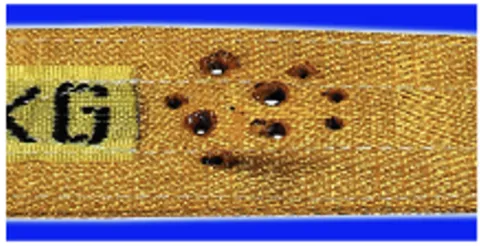

- Adanya Lubang. Lubang pada webbing sling SpanSet juga dapat mengurangi kekuatannya. Lubang ini dapat terbentuk akibat goresan atau tekanan berlebih pada webbing. Lubang dapat melemahkan webbing, membuatnya lebih rentan terhadap kerusakan dan kegagalan.

- Sering Terpapar Bahan Kimia. Webbing sling SpanSet yang sering terpapar bahan kimia dapat mengalami penurunan kualitas secara bertahap. Bahan kimia umum termasuk asam, alkali, dan minyak. Paparan terhadap bahan kimia ini dapat menipiskan webbing, membuatnya mudah putus dan kehilangan kekuatan. Selain itu, bahan kimia dapat menyebabkan korosi pada kawat pengikat, kait, dan bagian logam lainnya dari webbing sling SpanSet.

Penting bagi pengguna SpanSet untuk memahami tanda-tanda kerusakan pada webbing sling, baik dari SpanSet maupun merek lainnya, untuk mengambil tindakan yang tepat jika kerusakan ditemukan. Jika terdapat kerusakan signifikan, webbing sling SpanSet harus segera dihentikan penggunaannya dan diganti dengan yang baru. Jangan mencoba memperbaiki webbing sling yang rusak, karena ini dapat meningkatkan risiko kegagalan saat digunakan.

Selain mengenali tanda-tanda kerusakan pada webbing sling SpanSet, pengguna juga harus mengikuti panduan penggunaan yang diberikan oleh produsen. Pastikan pemeriksaan rutin dilakukan pada webbing sling SpanSet sebelum digunakan, serta lakukan perawatan dan penyimpanan yang benar untuk memastikan masa pakai yang lebih lama dan keselamatan yang lebih tinggi saat digunakan.

Kesimpulannya, mengenali tanda-tanda kerusakan pada webbing sling SpanSet sangat penting untuk menjaga keselamatan dan kinerja alat angkat tersebut. Memperhatikan kerusakan dan tanda-tanda keausan pada webbing sling SpanSet serta mengambil tindakan yang tepat saat diperlukan akan membantu mengurangi risiko kegagalan dan meningkatkan keselamatan saat digunakan. Jika Anda memiliki masalah terkait pemilihan webbing sling, round sling, rantai, atau kawat baja, konsultasikan kepada ahlinya.

Untuk konsultasi lebih lanjut mengenai produk dan layanan SpanSet Indonesia, silakan hubungi kami melalui email di sales@spanset.co.id atau WhatsApp

Untuk mengetahui spesifikasi dan harga Produk SpanSet Indonesia secara detail, silakan kunjungi Marketplace SpanSet di Tokopedia dan Shopee.