Ratchet Tie Down: A Key Tool for Safe Transportation

Ratchet tie down is one of the most commonly used securing devices in the logistics and transportation sectors. This tool is extremely useful for keeping items from shifting during transit. Although it seems simple, using a ratchet tie down correctly requires specific knowledge to ensure optimal function.

This article will discuss the proper way to use a ratchet tie down, safety tips, and important component details. With a good understanding, you can use it more effectively.

How to Use a Ratchet Tie Down

To ensure that the items secured with a ratchet tie down remain safe during transport, there are several basic steps you need to follow. Let's look at how to use a ratchet tie down properly:

1. Open the Handle

The first step is to open the ratchet handle. To do this, press the locking lever on the handle, then pull the handle up until it is fully open. By opening the handle, you are ready to start inserting the tie strap and adjusting it to the item you want to secure.

2. Access the Axle Assembly

After the handle is open, you will see the axle mechanism inside the ratchet. This component is crucial as it functions to roll and tighten the tie strap. Ensure that the axle is in good condition, without damage or rust, to facilitate a smooth securing process.

3. Insert the Strap

After opening the handle and exposing the axle, the next step is to insert the strap into the ratchet mechanism. The strap should be inserted from under the axle, then pull until the end of the strap comes out the other side. Make sure the strap is in the correct position and free of twists that could disrupt the securing process.

4. Attach the Hooks

After inserting the strap, the next step is to attach the hooks at both ends of the tie strap to sturdy anchoring points, such as the frame of a truck or transport vehicle. The hooks are usually made from strong, rust-resistant steel, ensuring reliability in holding heavy loads.

5. Release the Slack

Before tightening the strap, it is important to release the slack in the tie strap. Pull the strap by hand until all slack is gone, ensuring that the strap properly covers the entire item to be secured. Remaining slack can interfere with the securing process and reduce the tool's effectiveness.

Also see: Sharp Corner Protectors for Safer and Longer Lasting Ratchet Lashing | Ngedeprok Eps 2

6. Tighten the Slack

After releasing the slack, it's time to tighten the strap using the ratchet. Turn the ratchet handle back and forth to roll the strap onto the axle. Continue this until the strap feels tight and the secured item does not move. Be careful not to over-tighten the strap, as this can damage the item being secured or even the ratchet tie down itself.

7. Close the Handle

After the strap is tight, the final step is to close the ratchet handle. Press the locking lever on the handle again, then close the handle until it locks securely. This ensures that the strap will remain tight during transit and will not come loose even with bumps.

8. Release

After the items arrive at their destination and no longer require securing, you can start to release the ratchet tie down. This is done by opening the handle and pulling the locking lever to relieve the tension on the strap. After that, pull the strap out of the axle and detach the hooks from the anchoring points.

By following the steps above, you can use a ratchet tie down easily and safely.

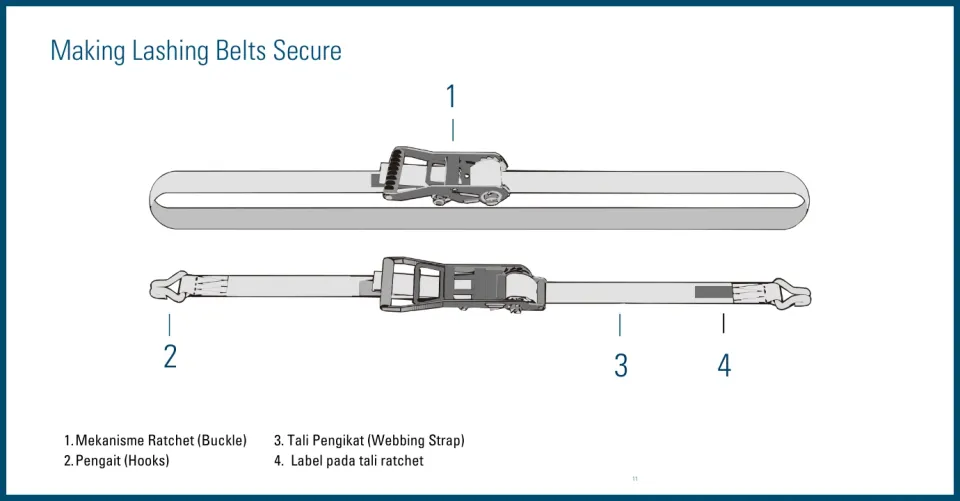

Details of Ratchet Tie Down Components

In addition to usage, understanding the components of a ratchet tie down is also important for better comprehension. Each part has its own function that supports the whole system.

1. Tie Strap (Webbing Strap)

The main component of the ratchet tie down is the tie strap. It is usually made of durable and strong polyester material. The length and width of the strap vary depending on the securing needs. Polyester is chosen for its excellent resistance to abrasion and exposure to extreme weather.

2. Hooks

At both ends of the strap, there are hooks that function to attach the strap to securing points. These hooks are typically made of rust-resistant steel, ensuring a strong grip during the securing process.

3. Ratchet Mechanism

The ratchet mechanism serves as a tool for easily tightening the strap. By moving the ratchet handle, the strap will become tighter, and the secured item will be more secure.

4. Locking Handle

The locking handle is the part that helps relieve the tension on the strap when you want to open it. By pulling this handle, the ratchet will loosen, and the strap can be released easily.

5. Axle Assembly

The axle is the part responsible for rolling the strap as you operate the ratchet handle. This component must function properly to ensure that the rolling of the strap goes smoothly without any hindrances. A well-maintained axle can prolong the lifespan of the ratchet tie down and maintain optimal performance.

6. Slack

Slack refers to the looseness in the tie strap that needs to be eliminated before tightening the ratchet. Releasing the slack helps ensure the strap is properly secured, and the item does not easily move. If slack is not removed, the tie can become loose, and the transported item is at risk of shifting during transit.

By following the correct steps and understanding each important component of the ratchet tie down, you can ensure that the transported items remain safe during transit.

So, do you agree that this tool is essential? Now is the time to purchase one for your safety! Get a strong and proven-quality ratchet tie down from SpanSet!

Click here to order now!

For further consultation about SpanSet Indonesia products and services, please contact us via email at sales@spanset.co.id or WhatsApp

To find specification detail and prices of SpanSet Indonesia Products, please visit SpanSet Indonesia Marketplace on Tokopedia and Shopee.