Have you ever inspected the condition of your sling before use? Many users often overlook this step, but even minor damage can lead to significant risks.

Slings are crucial components of lifting equipment, and their condition directly impacts workplace safety. Without regular inspections, hazards can arise. Let’s dive into the signs of sling damage and the proper usage standards to ensure safety.

Signs of Sling Damage

A damaged sling can lead to accidents, so recognizing early warning signs is critical. Here are common indicators:

1. Frayed or Broken Fibers

Frayed or broken fibers are the first signs of damage. These weaken the sling’s strength, making lifted loads unstable. According to data, slings with broken fibers can lose up to 50% of their load capacity. Never ignore these small damages—replace the sling immediately to ensure safety.

2. Corrosion on Metal Components

Corrosion is a major threat to metal-based slings. Rust makes the material brittle, increasing the likelihood of cracks under stress. If you notice rust, clean or replace the sling immediately. Opt for high-quality slings with anti-corrosion properties, like those offered by SpanSet.

3. Wear and Tear in Heavy Load Areas

Areas that frequently bear heavy loads often wear out faster. Signs include smooth or deformed surfaces. This wear can reduce the sling’s lifting capacity by up to 30%. Conduct routine inspections to prevent equipment failure.

4. Damaged Seams or Stitching

For fabric slings, check the seams and stitching. Any tears drastically reduce the sling’s strength. Even small tears can weaken its durability. Choose high-quality products with advanced stitching technology to minimize this risk.

5. Discoloration of Materials

Slings exposed to excessive heat or chemicals often change color. This indicates weakened material integrity. Always use slings that comply with temperature and chemical standards for your work environment. Certified slings ensure better safety.

After identifying these signs, it’s essential to follow proper usage standards to prevent damage.

Also read: Webbing Sling Colors and Capacities,Check It Out!

Usage Standards for Lifting Equipment

Lifting equipment must meet specific standards to guarantee safety and efficiency. These include:

- OSHA 1910.184 – Slings

- ASME B30.9 – Slings

- ASME B30.26 – Rigging Hardware

- ASME B30.10 – Hooks

- ASME B30.20 – Below-the-Hook Lifting Devices

- EN 1492-1 – Textile Slings

Best Practices for Sling Usage

1. Inspect the Lifting Belt Before Use

Ensure that lifting points are robust enough to support loads, including side loads.

2. Determine the Load Weight

The weight of the load can be found in cargo documents or construction data, or by weighing it directly. SpanSet offers cost-effective hanging scales for accurate measurements.

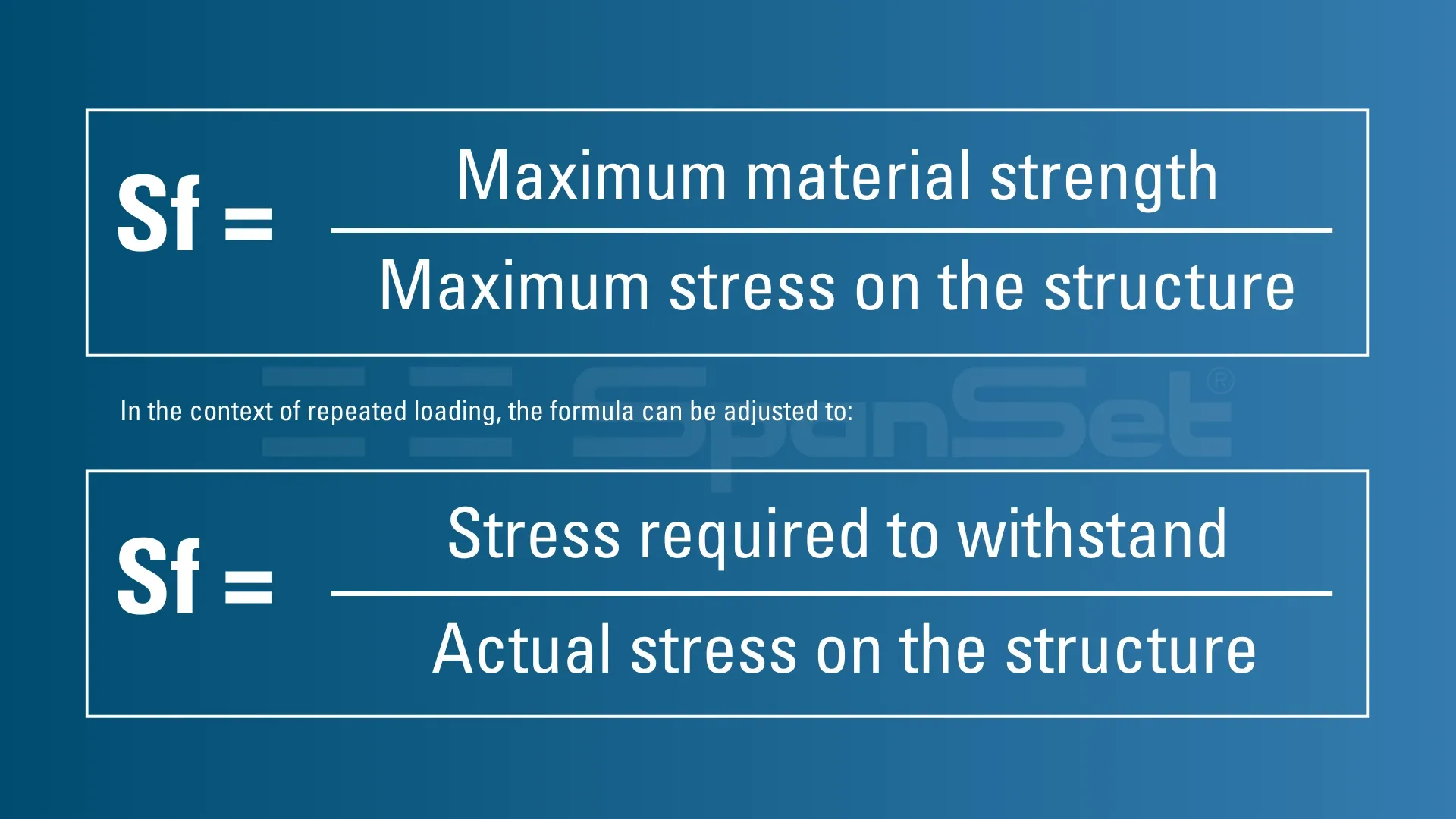

Based on the EN 1492-1 standard, the appropriate safety factor is 7:1. That is, if your Spanset Friend works using a webbing sling with a WLL (Working Load Limit) of 1 ton, the maximum strength of the tool is 7 tons. However, this does not mean that you can lift more than 1 ton, buddy!

Spanset pals are prohibited from lifting weights above 1 ton with the perpendicular lift method (direct pull). This prohibition applies because experts have calculated the WLL as a safe limit by considering various aspects, including the possibility of dynamic loads and material fatigue.

3. Focus on the Center of Gravity

The hook must be directly above the center of gravity. For asymmetric loads, adjustable-length web slings or connectors above the center of gravity are required. You can find such web slings at SpanSet.

4. Set the Inclination Angle

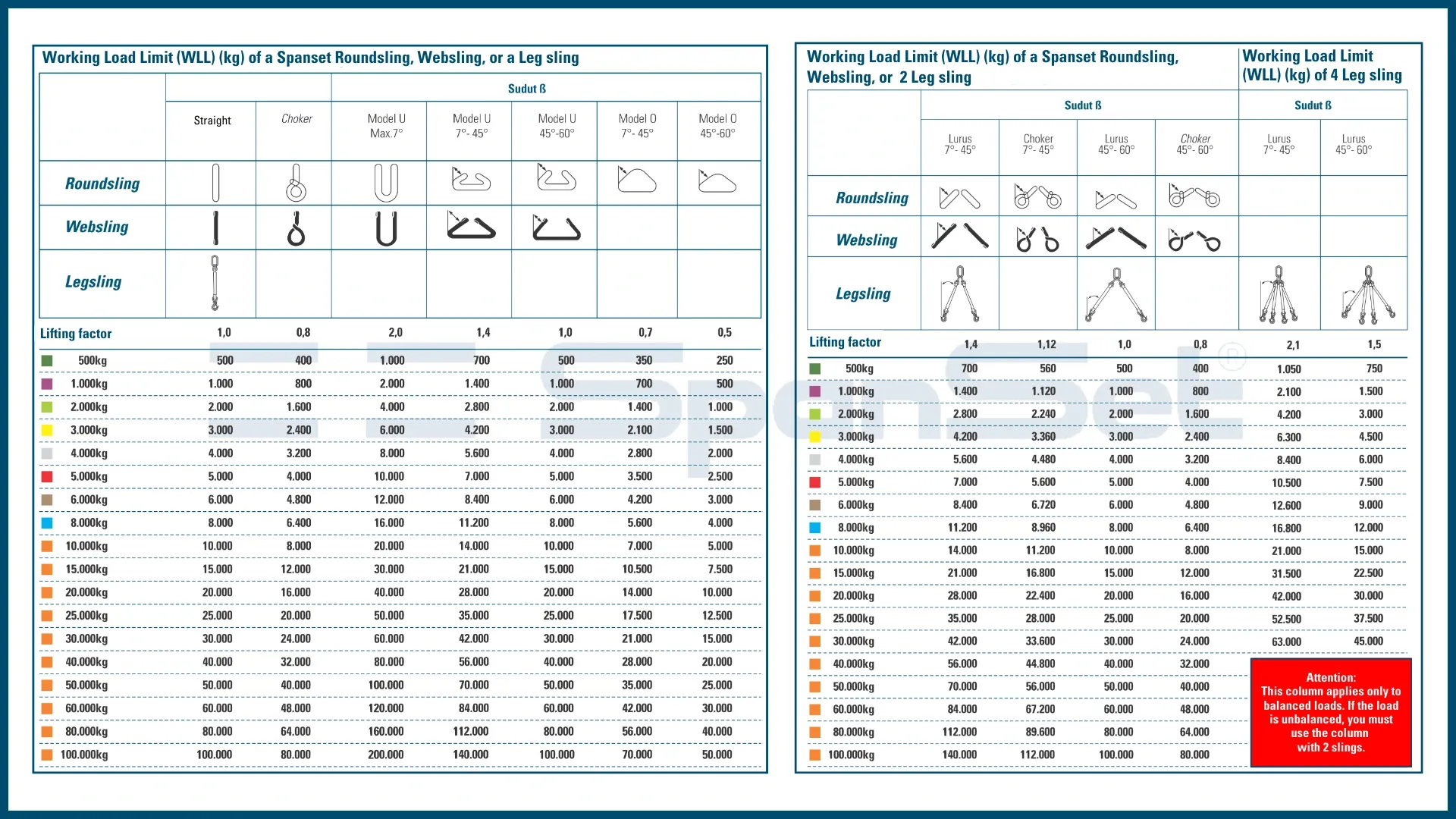

The maximum inclination angle between the belt and the load is 60 degrees. You can easily verify this with a calculation table.

5. Ensure Lifting Safety

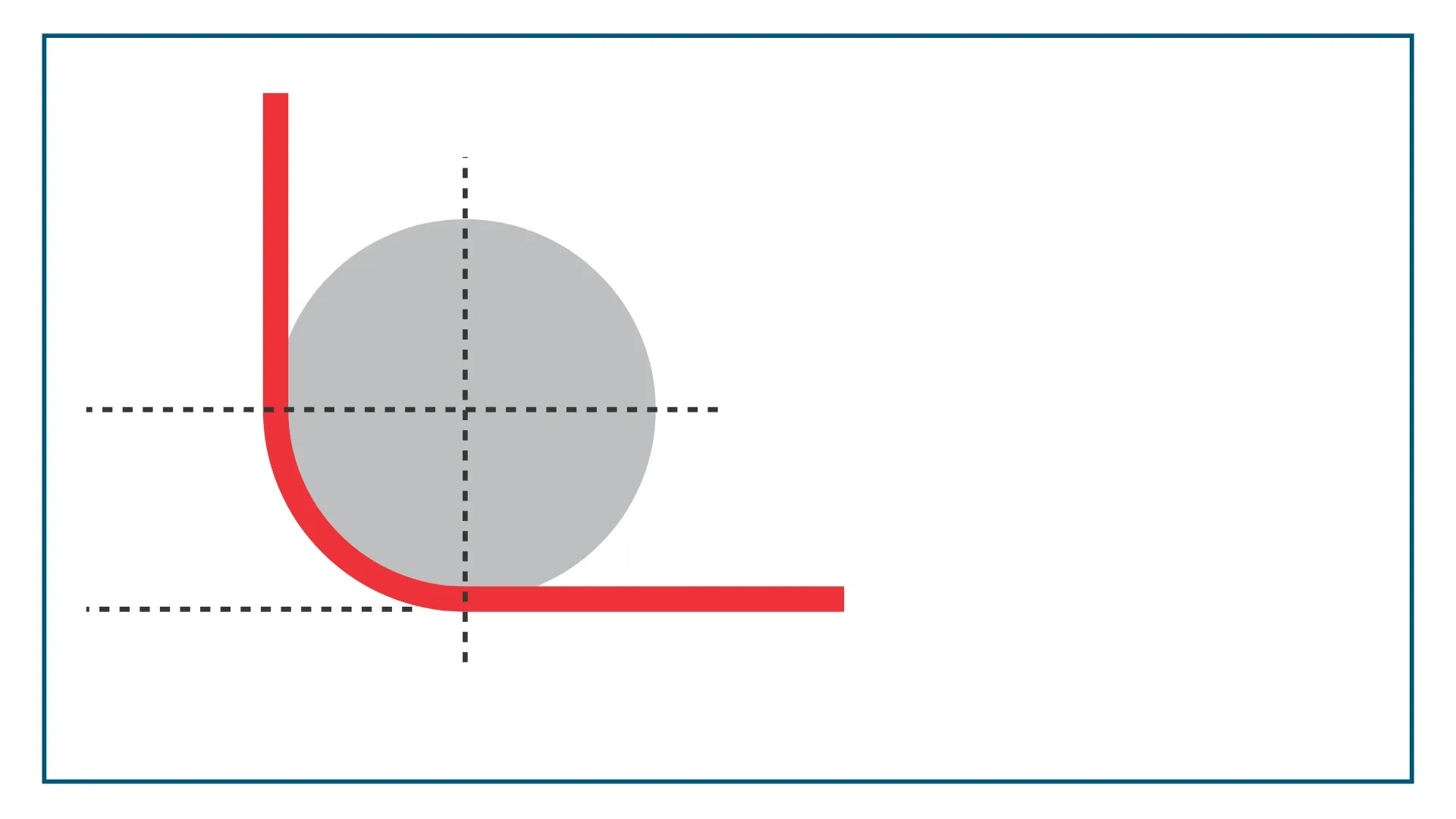

If the radius (r) of a sharp angle is smaller than the belt's thickness (d), it is considered a sharp angle. Use protective sleeves to safeguard the belt against wear and tear.

6. Avoid Tying or Knots

Joining two slings or tying knots reduces their lifting capacity drastically, increasing the risk of accidents. Instead, use tools like Joker hooks for safe length adjustments.

SpanSet Products Meet Lifting Equipment Standards

SpanSet is a leading brand in the lifting industry, offering high-quality products that adhere to international safety and quality standards.

1. Webbing Sling SpanSet

- Made from premium polyester.

- Withstands heavy loads with high strength.

- Complies with ISO 9001 and EN 1492-1 standards for safe use across industries.

2. Chain Sling SpanSet

- Built with top-quality steel for durability and heavy-duty applications.

- Meets EN 818-4 international standards.

3. Lifting Gear SpanSet

- Includes hoist rings and rigging equipment.

- Certified with CE marks and DIN standards for safety and reliability.

With SpanSet, you receive quality, compliance, and exceptional service to meet your lifting needs.

👉 Explore our lifting products today!