Apa Bedanya Round Sling Belt dan Webbing Sling? Ini Jawabannya!

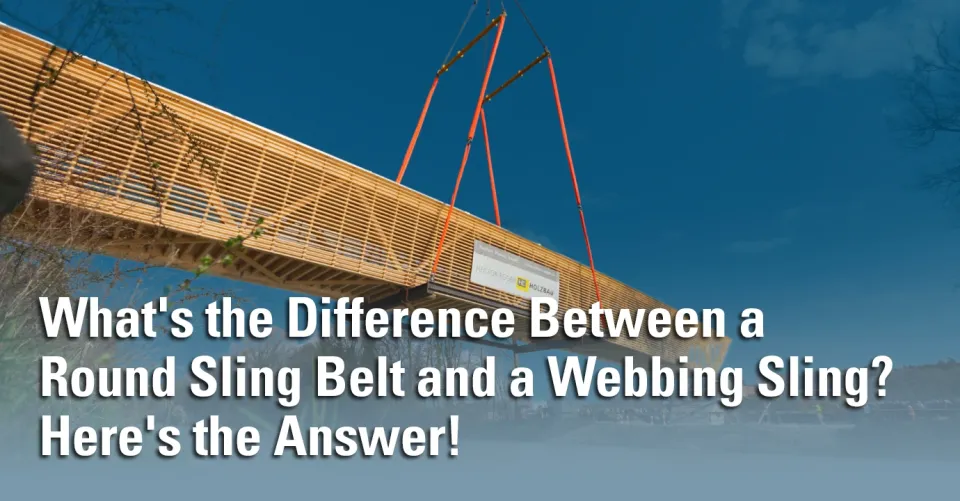

Dalam industri pengangkatan dan pemindahan beban, peralatan seperti round sling belt dan webbing sling sering kali menjadi pilihan utama. Namun, banyak yang belum sepenuhnya memahami perbedaan antara kedua jenis sling ini.

Padahal, memilih sling yang tepat sangat penting untuk memastikan keamanan dan efisiensi kerja. Dalam Artikel ini, kami ingin membantu Anda memahami perbedaan penting antara round sling belt dan webbing sling. Yuk, simak artikel ini untuk menemukan jawabannya!

Differences Between Round Sling Belt and Webbing Sling

Before delving into the specific differences, it’s important to understand that both types of slings are used for the same purpose: lifting and moving heavy loads. However, their usage methods and the materials used create significant differences in strength, flexibility, and durability.

Here, we will outline the main differences between round sling belts and webbing slings so that you can better understand the advantages of each.

1. Material and Construction

Round sling belts are made from synthetic fibers twisted into a tubular shape. These fibers are layered to provide even strength throughout the sling. The circular shape makes round sling belts more flexible and easier to shape when used.

On the other hand, webbing slings are made from woven synthetic fibers arranged flat like a ribbon. Because they are flat, webbing slings are easier to wrap around flatter load surfaces, such as wood or concrete. However, webbing slings tend to be stiffer compared to round sling belts, especially when lifting irregularly shaped loads.

2. Load Capacity

Load capacity is one of the key factors that distinguish these two tools. Round sling belts typically have a higher load capacity because their circular structure can distribute pressure evenly. Thus, this tool is better suited for lifting heavy loads that do not have a standard shape.

In contrast, webbing slings are suitable for lighter or medium loads. Due to their flat nature, webbing slings are easier to use on loads with flat and solid surfaces. The load capacity of webbing slings is usually slightly lower, but they remain reliable for various field applications.

Also see: Webbing Sling and Round Sling Materials in 5 Minutes One Episode 1

3. Flexibility and Usage

Round sling belts are known for their high flexibility. Their circular shape allows these slings to adapt to uneven or hard-to-reach load shapes. Therefore, round sling belts are often used in applications requiring lifting of irregularly shaped loads, such as machinery or large pipes.

Conversely, webbing slings are more suitable for use on loads with flat and accessible surfaces. Because they are stiffer, webbing slings are more ideal for jobs that do not require extra flexibility. Additionally, webbing slings are quicker to install and release, making them suitable for time-sensitive tasks.

4. Resistance to Abrasion and Environment

Resistance to abrasion and environmental factors is also an important consideration. Round sling belts are usually more durable because their outer protective layer is thicker, making them less likely to be damaged by friction. This makes round sling belts more suitable for use in harsh environments, such as construction sites or heavy industrial areas.

In contrast, webbing slings tend to be more vulnerable to abrasion, especially if used on rough surfaces. However, some types of webbing slings come with additional protective layers that can enhance their resistance to friction and other environmental factors.

After discussing these main differences, it’s important for you to choose the sling that best fits the specific needs of your project.

By considering all the factors mentioned above, you can make a more informed choice about which type of sling is best suited for your operational needs.

As a leading company in the field of lifting equipment, SpanSet offers a variety of webbing slings that guarantee your safety! Interested in purchasing this equipment? Contact us now and take advantage of our special offer today!

For further consultation about SpanSet Indonesia products and services, please contact us via email at sales@spanset.co.id or WhatsApp

To find specification detail and prices of SpanSet Indonesia Products, please visit SpanSet Indonesia Marketplace on Tokopedia and Shopee.