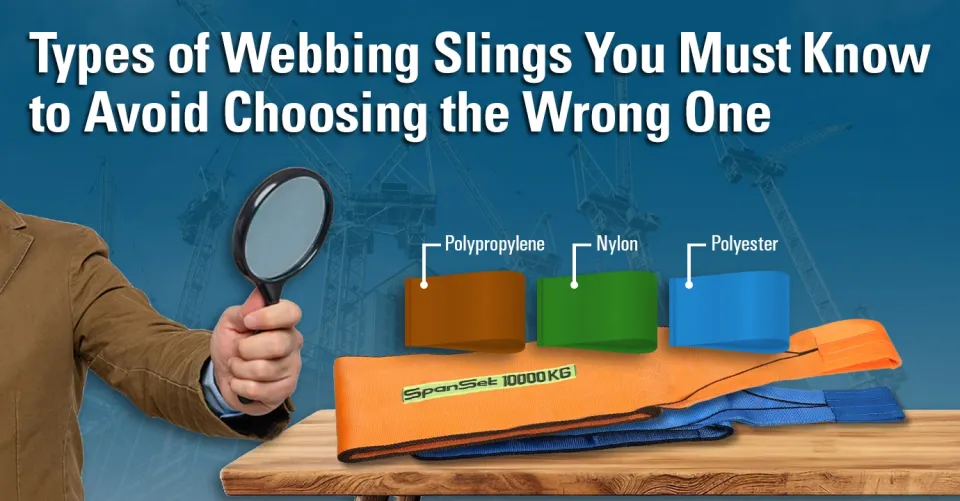

Types of Webbing Slings You Must Know to Avoid the Wrong Choice

When working with lifting equipment, webbing slings become one of the most essential tools. However, many people are still confused about choosing the right type of webbing sling for their needs. In this article, we will discuss several types of webbing slings that you should know about. With a better understanding, you can ensure both safety and work efficiency.

Types of Webbing Slings

Here are the types of webbing slings frequently used by workers at heights. Let’s dive in to learn about their characteristics!

1. Polyester Webbing Sling

Polyester webbing slings are one of the most commonly used types across various industries. Polyester is known for its strength and durability, making it ideal for lifting heavy loads with frequent use.

These slings are also resistant to moisture and ultraviolet light! However, keep in mind that polyester is less suitable for environments with harsh chemicals as it can damage the fibers.

2. Nylon Webbing Sling

If you need a webbing sling that is elastic and resistant to oil, nylon webbing sling is the right choice. Its elasticity provides better flexibility when lifting, allowing the load to be distributed more evenly.

Unfortunately, nylon webbing slings are more vulnerable to UV exposure and high humidity. Therefore, this type is not recommended for tasks involving direct sunlight.

3. Polypropylene Webbing Sling

As the name suggests, this sling is made from polypropylene, which is very lightweight yet strong. Polypropylene webbing slings are typically used for lighter loads compared to polyester or nylon.

Polypropylene is more resistant to chemicals than nylon or polyester, making it suitable for industrial environments exposed to hazardous substances. However, its load-bearing strength is not as high as the other types.

4. Round Sling

Unlike other types, the round sling has a circular shape and is covered with synthetic material, making it very flexible. Round slings are usually used for heavier loads and are perfect for lifting irregularly shaped objects.

Round slings are also less likely to damage the surface of the lifted object due to their soft outer layer. However, it is harder to inspect for internal damage since the outer layer is enclosed.

5. Wire Rope Sling

The last type is the wire rope sling, which offers the highest strength. Made of steel wire, wire rope slings are used in large projects such as building construction or lifting heavy machinery.

While very strong, wire rope slings lack flexibility. Their use is more complicated and requires extra maintenance to ensure they remain safe over a long period.

Conclusion

After understanding the types of webbing slings above, do you know which one is suitable for your company? If you're still unsure, feel free to contact us for further consultation.

SpanSet is the right choice for your lifting equipment needs! We provide high-quality, safe webbing slings for various heavy lifting applications. So, what are you waiting for? Make SpanSet your top choice!

Also, check out the "Types of Webbing Slings and 7 Must-Have PPE" on our official YouTube channel, SpanSet Indonesia!

For further consultation about SpanSet Indonesia products and services, please contact us via email at [email protected] or WhatsApp

To find specification detail and prices of SpanSet Indonesia Products, please visit SpanSet Indonesia Marketplace on Tokopedia and Shopee.